Add Your Heading Text Here

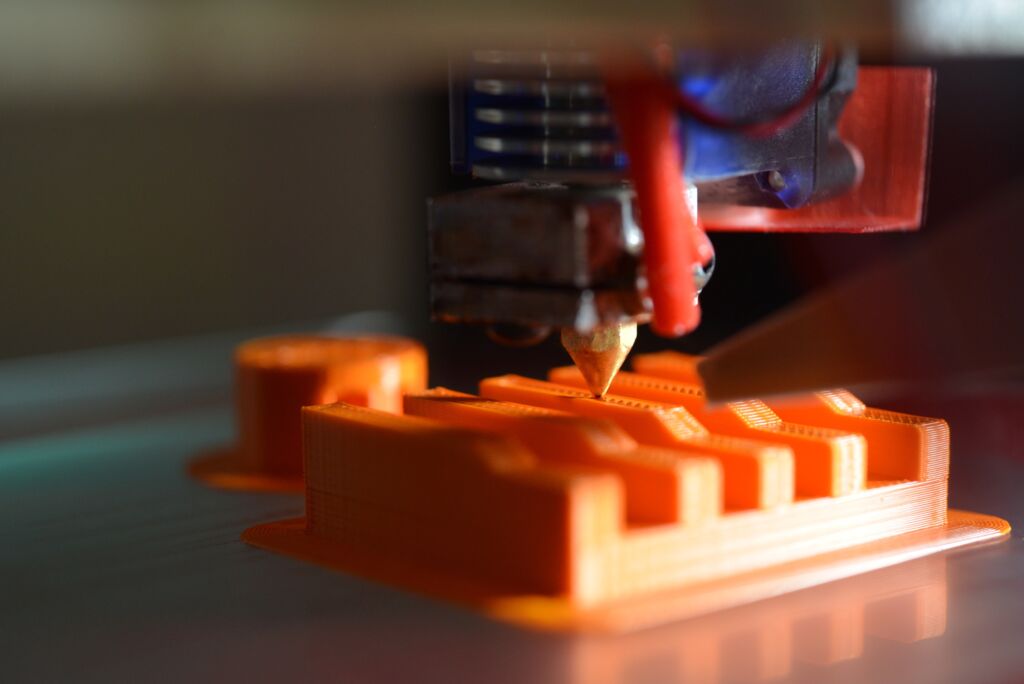

FDM is a 3D printing technology in which the thermoplastic material melted by a hot nozzle is poured and added on the printing plate layer by layer. For this production method, the names “Fused Deposition Modeling” (FDM) or “Fused Filament Fabrication” (FFF) are used.

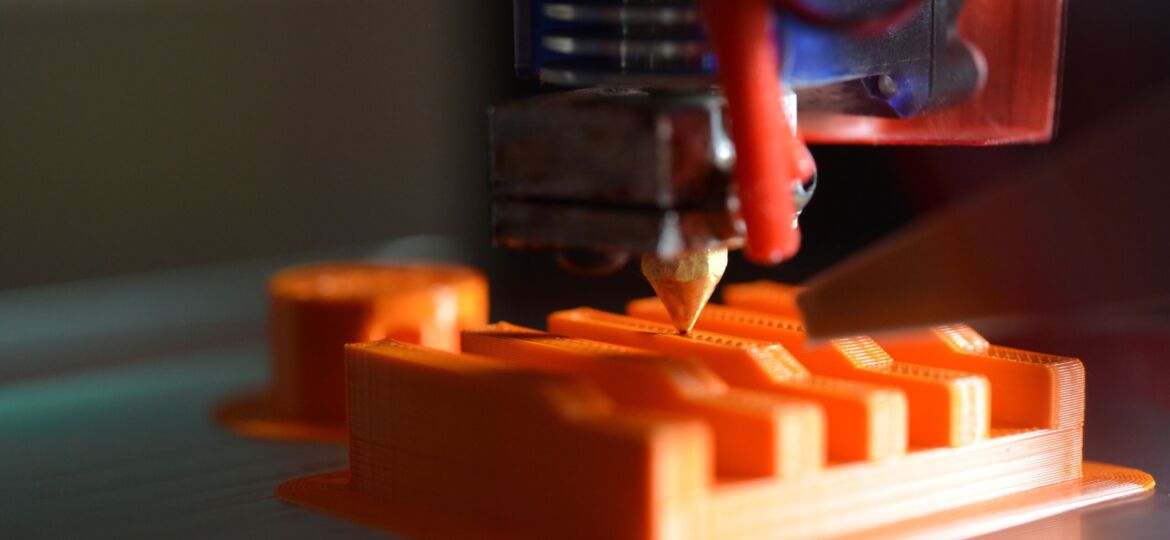

Thanks to the wide range of thermoplastic materials offered by the technology, the model can be produced with the most suitable material for the desired mechanical properties. Materials used for production in Tridi; ABS, PLA, PCABS, ABS+, TPU, PC, PEEK, ULTEM, PP are thermoplastics.

With FDM, custom thermoplastic parts and prototypes can be produced cost-effectively. Delivery times are short. A wide range of thermoplastic materials are available that are suitable for commercial or non-commercial production.