Injection molding

Transform your ideas into reality with our injection molding services! Simply upload your designs, get a quick and precise quote, and watch as your parts come to life in record time.

How it's working?

Inspection

We use the golden sample to verify future orders and provide additional QC checks.

Delivery

Enjoy your parts.

Our custom injection molding services

Whether you’re looking for small parts, like computer keys, or large parts, such as car bumpers, we’ve got you covered with a wide range of sizes and complexities. From rapid prototypes to production parts, our experienced project engineers are dedicated to helping you through every step of the ordering process. We take pride in offering top-quality parts and expert guidance to ensure that your project is a success.

Injection molding prototypes

Boasting a quick turnaround time and impressive cost efficiency, this solution is perfect for those seeking to quickly produce prototypes or carry out low-volume production runs. Whether you're looking to test out a new design or create a limited number of parts, this option offers the speed and affordability you need.

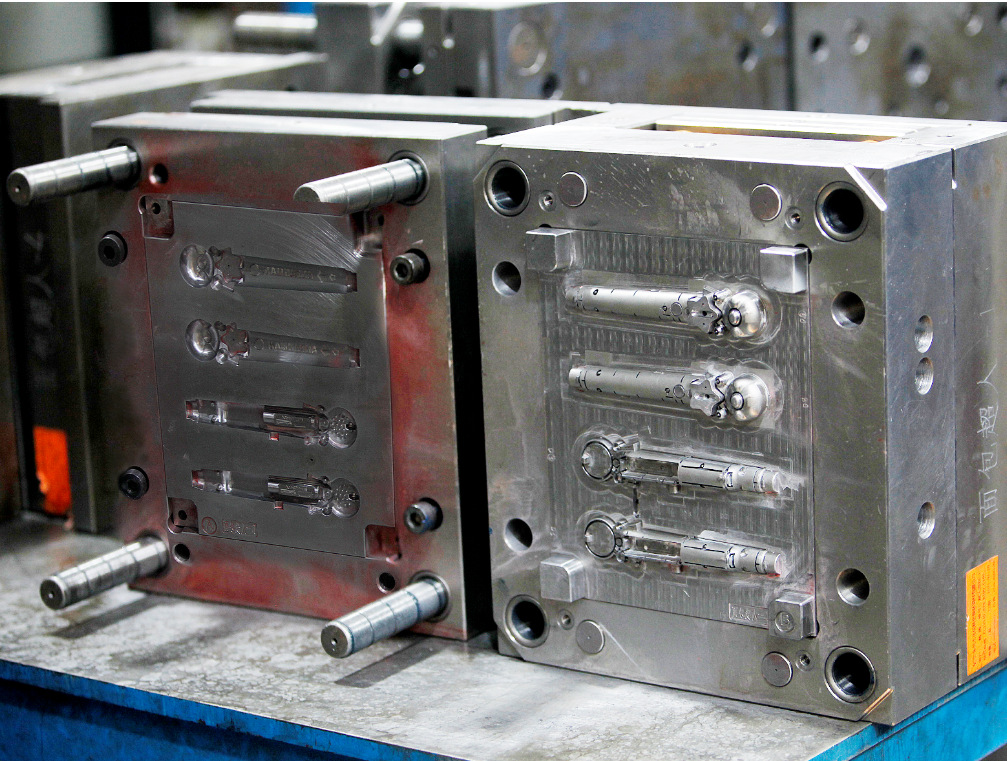

- Family Mold

- Insert mold/MUD tool

Typical Shot Life: 5k to 10k

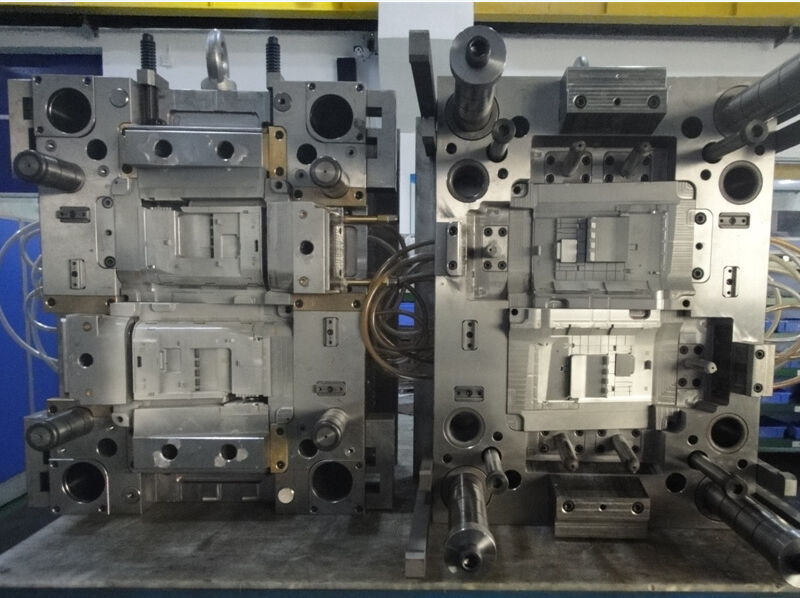

Production tooling

Constructed from high-quality steel, providing exceptional durability and extending the lifespan of your tools. With increasing volumes, the unit price becomes even more cost-effective, making it a highly scalable option for your needs.

- Multi-cavity mold

- Tool steel

Typical Shot Life: 50k to 1M

Capabilities

Injection molding

- Large parts (up to 1.5 meters, 59 in)

- No minimum order quantity for production volume

- Cosmetic parts

- Thin-walled applications (as low as 0.25 mm, 0,001 in)

- Threaded inserts

- Overmolding

- Simple assembly

Secondary operations

- Inserts

- Pad printing

- Painting

- Silk screening

- Ultrasonic welding

- Laser engraving

- UV coating

- Heat staking

- Hot stamping

- Post-mold machining

Materials

With a vast selection of plastics available for use in injection molding, the possibilities are nearly endless. From common materials to more specialized options, we have access to thousands of plastics and can source them quickly to meet your specific needs. No matter your industry or application, we have the expertise and resources to deliver high-quality parts made from the ideal material for your project.

Please contact us for specific material requests!

- ABS

- PMMA

- PVC

- PC

- PE

- POM

- PEEK

- UHMW

- ABS

- PBT

- HIPS

- PPS

- PEEK

- PP

- PBT

- PE

- LDPE

- HDPE

- PA

- PVC

- TPU

- TPE

- Silicone

- ABS

- PP

- HDPE

- LDPE

- ABS,

- PC

- HIPS

Injection molding surface finishes

SPI surface finishes

At 3D Berg, we follow the lead of the Society of the Plastics Industry (SPI) in setting the industry standard for plastics quality in the United States. This means that we utilize the SPI's comprehensive system to define the surface finish of our injection molded parts. With twelve different grades of finishes to choose from, spanning four different categories ranging from glossy to matte, we can deliver the perfect level of surface finish for your specific needs. Additionally, each grade comes with its own set of criteria for allowable deviation, ensuring that your parts are crafted to the exact specifications you require.

| SPI Finish | Guide | Typical Applications | Steel | Hardness |

|---|---|---|---|---|

| A-1 | Grade #3 Diamond | Lens / Mirror – requires 420 SS material | S136 | 54HRC |

| 8407 | 52HRC | |||

| A-2 | Grade #6 Diamond | High Polish parts | DF-2 | 58HRC |

| XW-10 | 60HRC | |||

| A-3 | Grade #15 Diamond | High Polish parts | S136 | 300HB |

| 718SUPREME | 300HB | |||

| B-1 | 600 Grit paper | Medium Polish parts | ||

| B-2 | 400 Grit paper | Medium Polish | ||

| B-3 | 320 Grit paper | Med – Low polish | ||

| C-1 | 600 Stone | Low Polish parts | ||

| C-2 | 400 Stone | Low Polish parts | ||

| C-3 | 320 Stone | Low Polish parts | ||

| D-1 | Dry Blast Glass Bead | Satin finish | ||

| D-2 | Dry Blast # 240 Oxide | Dull Finish | ||

| D-3 | Dry Blast # 24 Oxide | Dull finish |

VDI surface finishes

Similar to the SPI standard for plastics quality in the United States, the VDI (Verein Deutscher Ingenieure) standard sets the benchmark for the engineering industry in Germany. At 3D Berg, we adhere to the VDI's rigorous standards when it comes to designing and manufacturing our precision injection molded parts. By following the VDI's exacting guidelines, we can ensure that our products meet the highest levels of quality and precision, delivering outstanding performance and longevity for your specific application. Whether you need parts that can withstand extreme temperatures, resist corrosive materials, or provide superior strength and durability, we have the expertise and resources to deliver exceptional results.

| VDI | Raum | Yick Sang Texture | Ra | Minimum Draft Angle | Recommended Draft Angle |

| 0 | 0.10 | YS20037 | 0.56 | 0.2 | 0-0.2 |

| 3 | 0.15 | YS20037 | 0.56 | 0.2 | 0.1-0.2 |

| 6 | 0.20 | YS20037 | 0.56 | 0.2 | 0.1-0.2 |

| 9 | 0.30 | YS20037 | 0.56 | 0.2 | 0.1-0.2 |

| 12 | 0.40 | YS20037 | 0.56 | 0.2 | 0.15-0.2 |

| 15 | 0.55 | YS20037 | 0.56 | 0.2 | 0.2 |

| 18 | 0.80 | YS20039 | 0.92 | 0.3 | 0.3 |

| 21 | 1.10 | YS20040 | 1.09 | 0.5 | 0.5 |

| 24 | 1.60 | YS20002 | 2.14 | 1.5 | 1-1.5 |

| 27 | 2.20 | YS20002 | 2.14 | 1.5 | 1.5 |

| 30 | 3.20 | YS20046 | 3.26 | 2 | 2 |

| 33 | 4.50 | YS20007 | 4.50 | 3 | 3 |

| 36 | 6.30 | YS20070 | 6.28 | 3 | 3 |

| 39 | 9.00 | YS20069 | 9.17 | 5 | 5 |

| 42 | 12.50 | YS20028 | 11.94 | 6 | 6 |

| 45 | 18.00 | 10 | 10 |