"Designing for Success: Tips for Creating High-Quality 3D Printed Parts"

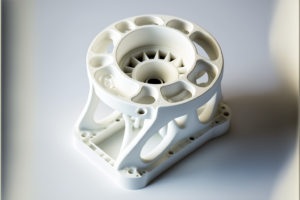

3D printing is a rapidly growing manufacturing process that allows for the creation of complex and intricate parts. However, in order to achieve the best results, it's important to keep certain design principles in mind. In this blog post, we'll be sharing some key tips to keep in mind when designing for 3D printing to help you create high-quality parts every time.

- Keep it simple

One of the most important things to keep in mind when designing for 3D printing is to keep it simple. Complex designs can be difficult to print and increase the risk of errors. Simple geometries are often easier to print and require less time and resources. By keeping your designs simple, you can reduce the chances of errors and improve the overall quality of your parts.

- Optimize for your printing method

There are many different 3D printing technologies, each with their own strengths and limitations. It's important to optimize your design for the specific printing method you will be using. For example, if you're using Fused Deposition Modeling (FDM) printing, you'll want to pay attention to wall thickness and avoid overhangs. If you're using Stereo lithography (SLA) printing, you'll want to pay attention to the size of the build platform and the minimum feature size. By optimizing your design for your printing method, you can improve the quality of your parts and reduce the chances of errors.

- Pay attention to wall thickness

The walls of your design should be thick enough to support the weight of the part but not so thick as to increase printing time and material usage. The ideal wall thickness will vary depending on the specific printing method you're using, so be sure to check the manufacturer's recommendations. By paying attention to wall thickness, you can improve the quality of your parts and reduce the chances of errors.

- Use support structures

Some designs may require support structures to ensure proper printing. Be aware that the support structures are generated by the slicing software and not part of the original design. When designing for 3D printing, it's important to be mindful of the orientation of your part, and avoid overhangs as much as possible, to minimize the need for support structures.

- Avoid overhangs as much as possible

Overhangs can cause problems during printing, such as warping or sagging. To avoid this, try to design features with larger radiuses or shallower angles, or make use of the support structures. By avoiding overhangs, you can improve the quality of your parts and reduce the chances of errors.

- Be mindful of the orientation

The orientation of your design can affect the final quality of your print. Be sure to orient your design in a way that minimizes the need for support structures and maximizes the strength of the part. By being mindful of the orientation, you can improve the quality of your parts and reduce the chances of errors.

In conclusion, by following these tips, you'll be well on your way to creating stunning, high-quality 3D printed parts. 3D printing is a rapidly growing technology and the design principles are constantly evolving, so be sure to stay informed and up-to-date with the latest advancements in the field. Happy printing! #3DPrinting #design #manufacturing

If you're interested in learning more about 3D printing and its application in various fields, check out our blog for more informative articles. Also, if you're looking for a reliable 3D printing service, we offer a wide range of options for various industries and applications."